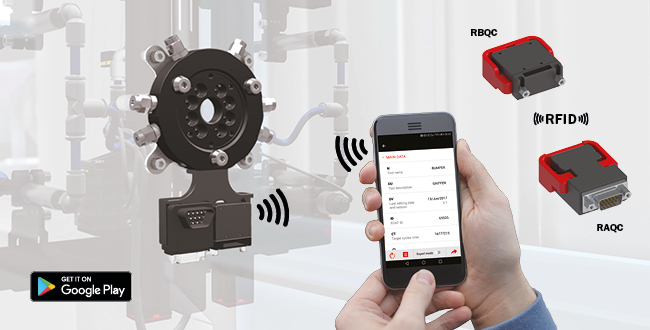

How can I identify my End Of Arm Tool

How It works:

- All kinds of data can be stored in a small module (RBQC) mounted on the End Of Arm Tool

- This data can be read:

- Via an App on a mobile device

- Through The robot via a module placed on the robot arm (RBQC)

Applications:

- Operator and robot can identify the End Of Arm Tool and prevent it from being used on the wrong mould or robot

- The number of cycles can be recorded and linked to a preventive maintenance report

- Technical information stored on the End Of Arm Tool (weight, dimensions, mass-inertial moment) provide information about the employability

- A list of components and spare parts stored on the End Of Arm Tool avoid research in case of overhaul or repair

- Backup this information in the cloud

- Through the Gimatic Web Service, you can monitor globally in which plant or at which sub-contractor each End Of Arm Tool is in and how it is used and maintained

Check Out the video and contact us for a demonstration